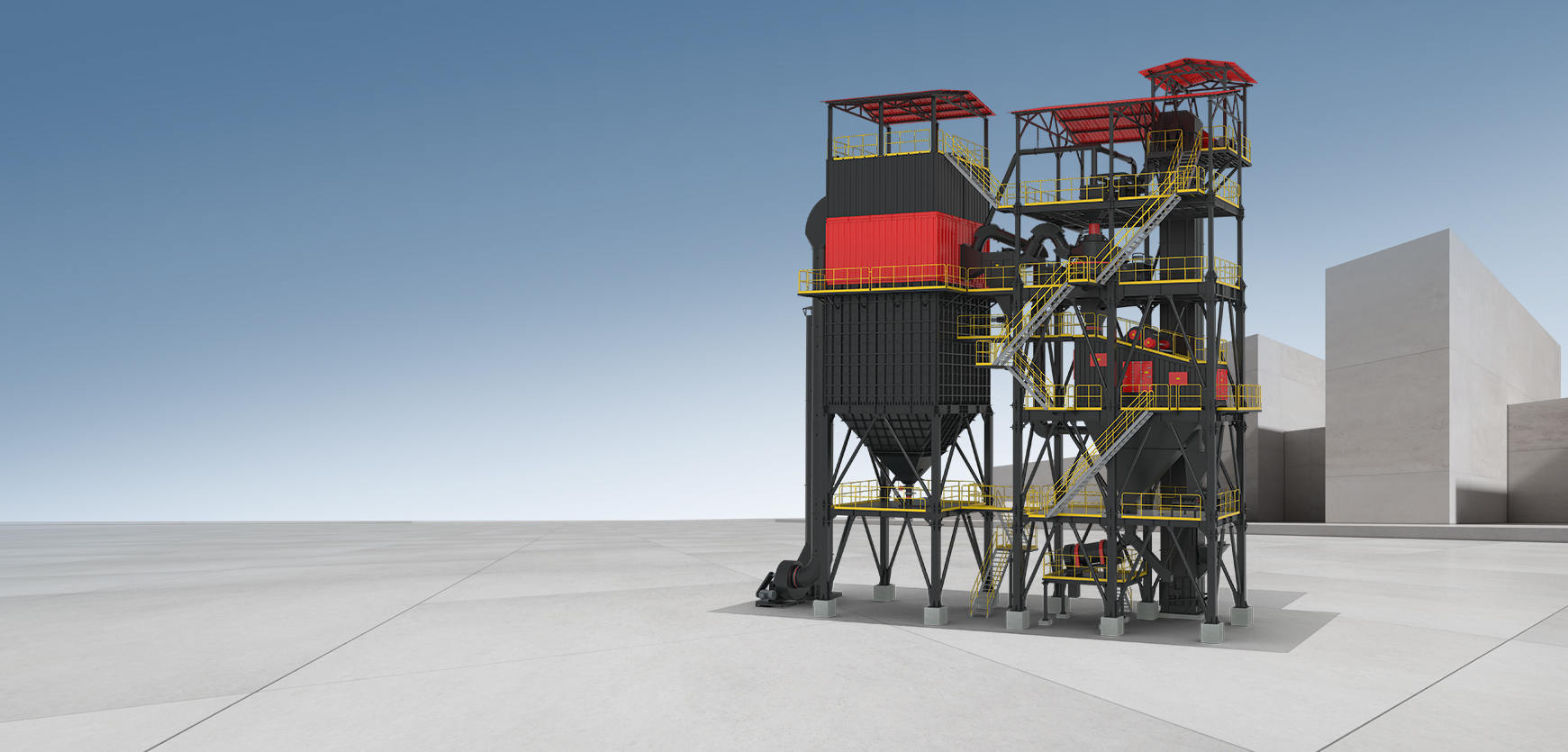

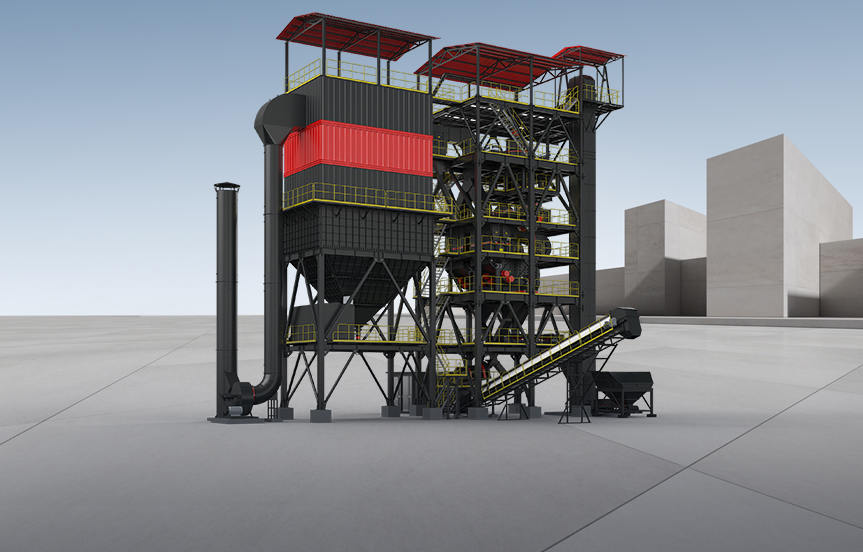

Working Principle

The sand making building adopts a chute design in terms of the connection method of modular equipment. During the sand making process, the raw materials enter the sand making and powder selection integrated machine, high-frequency screen, powder selection machine and other equipment in sequence through the chute through the principle of gravity from top to bottom. No additional elevators, conveyors and other equipment are required for auxiliary operations, which effectively reduces the dust points of the production line and also reduces the probability of failure. The entire production process adopts a centralized control system, which can realize online monitoring of the production process and real-time adjustment of the operation of the entire set of equipment, and has one-button start and stop, abnormal alarm, emergency shutdown and other functions, which can ensure the quality of the finished sand and the safety and stability of the production process.

Chat Online