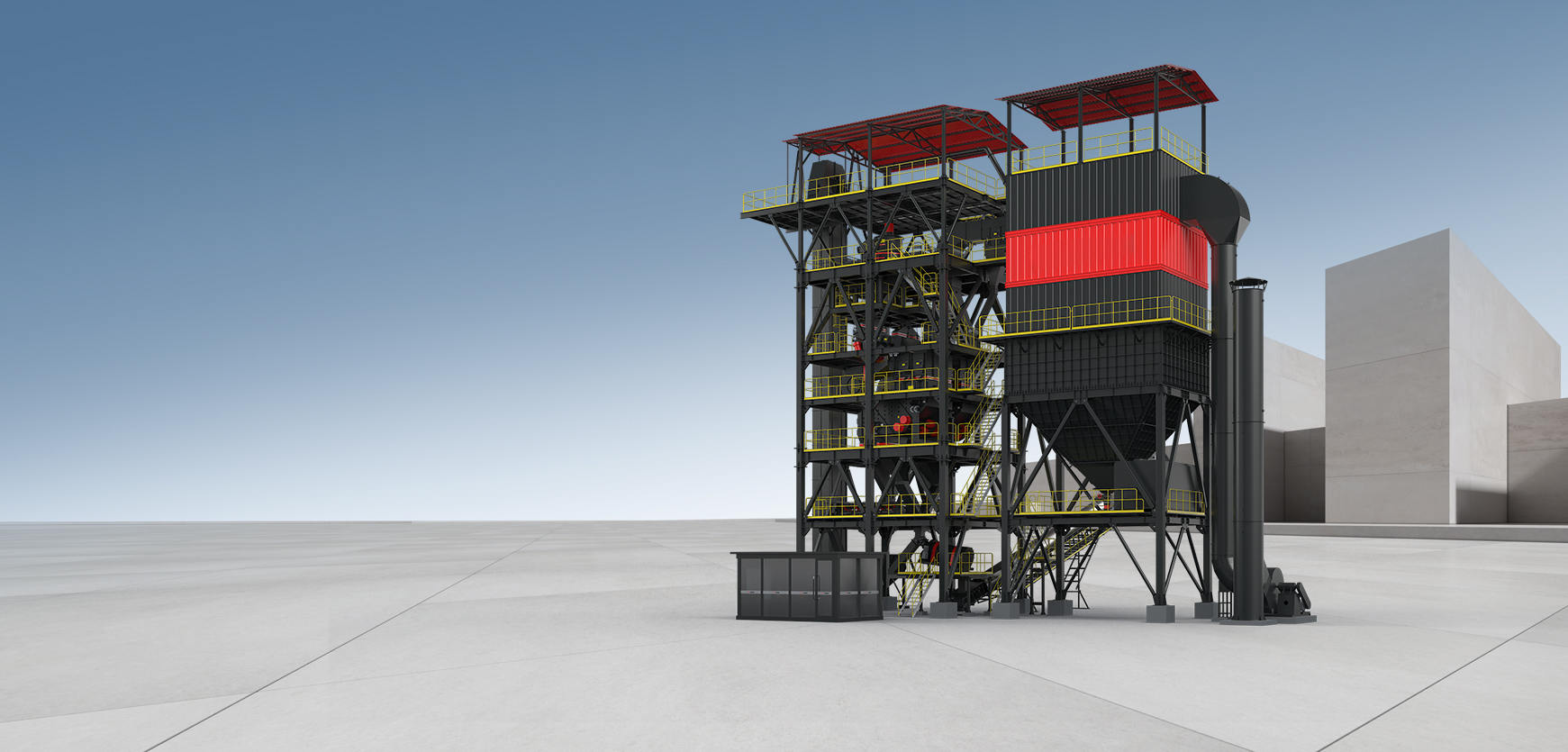

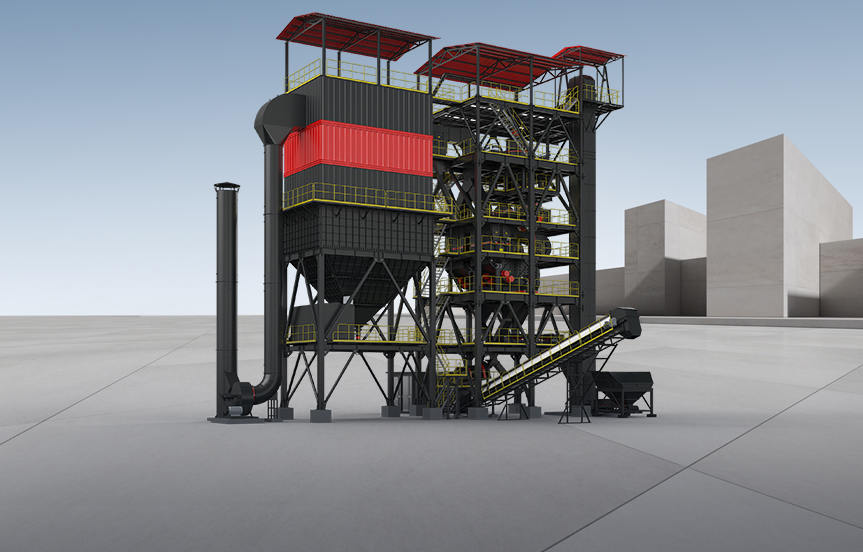

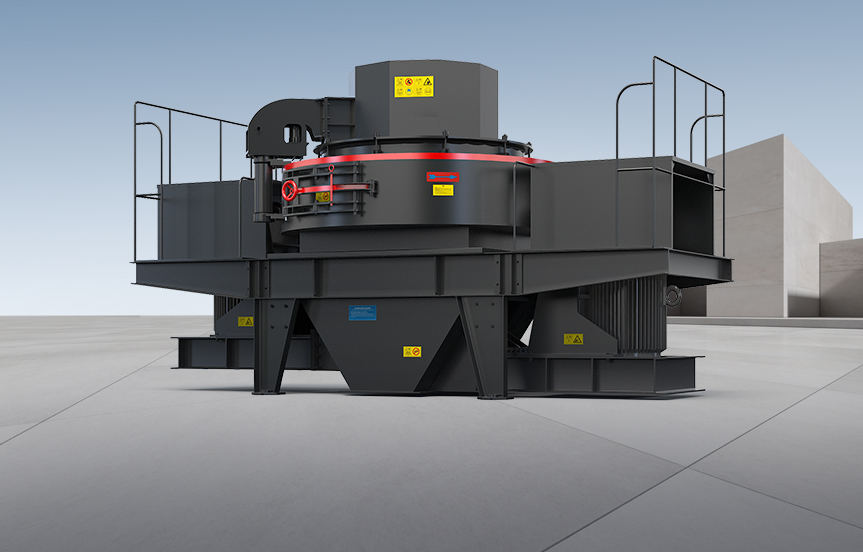

S7 Dry Process Premium Sand Making Tower is based on our company's digestion and absorption of the international advanced dry sand making concept, in order to meet the high reliability and high performance requirements of customers such as high-quality sand and gravel quarries, cement plants, mixing plants, etc. The most advanced crushing, screening, dust removal, powder selection and intelligent control technology, complete sets of equipment developed and produced. It is widely used in mining, building materials, transportation, energy, chemical and other industries.