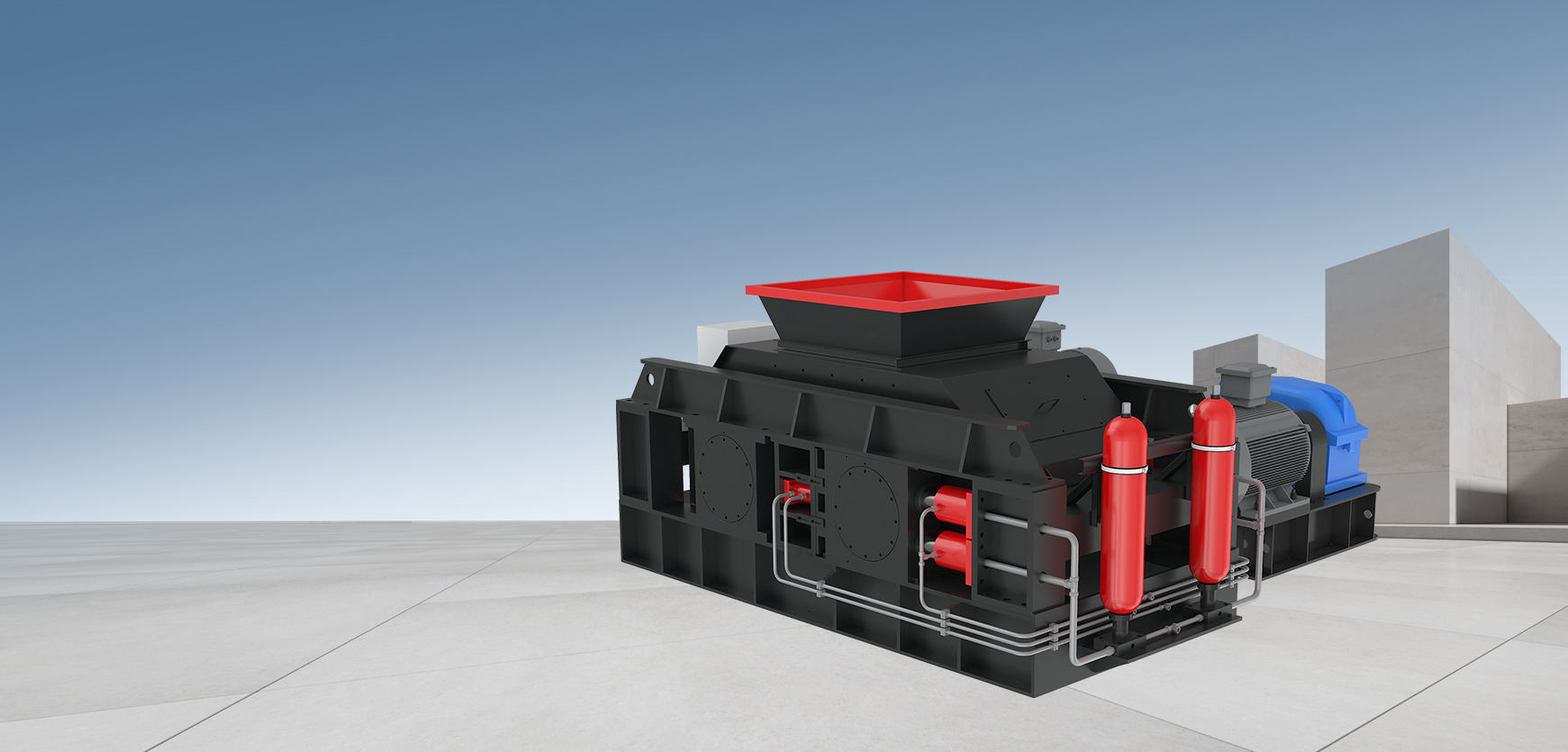

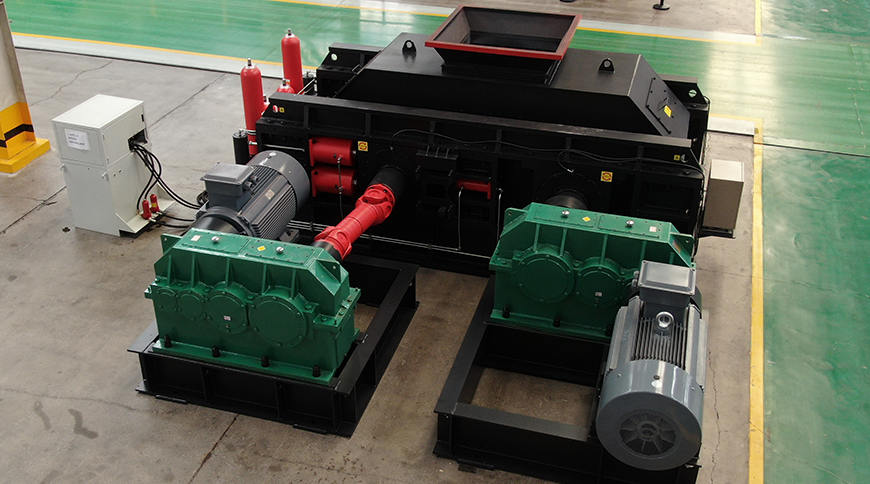

The hydraulic roller crusher is a new type of roller crusher that combines various advanced technologies. It has reasonable structure, advanced performance and powerful functions. Through excellent electromechanical and hydraulic integration design, the equipment can operate continuously, stably and reliably. In aggregate and grinding systems, it can generally increase the output by 30% - 40% and reduce the total energy consumption by 20% - 30%. It can finely crush materials of various hardness In mineral processing, chemical industry, refractory, stone processing, building materials and other industries.