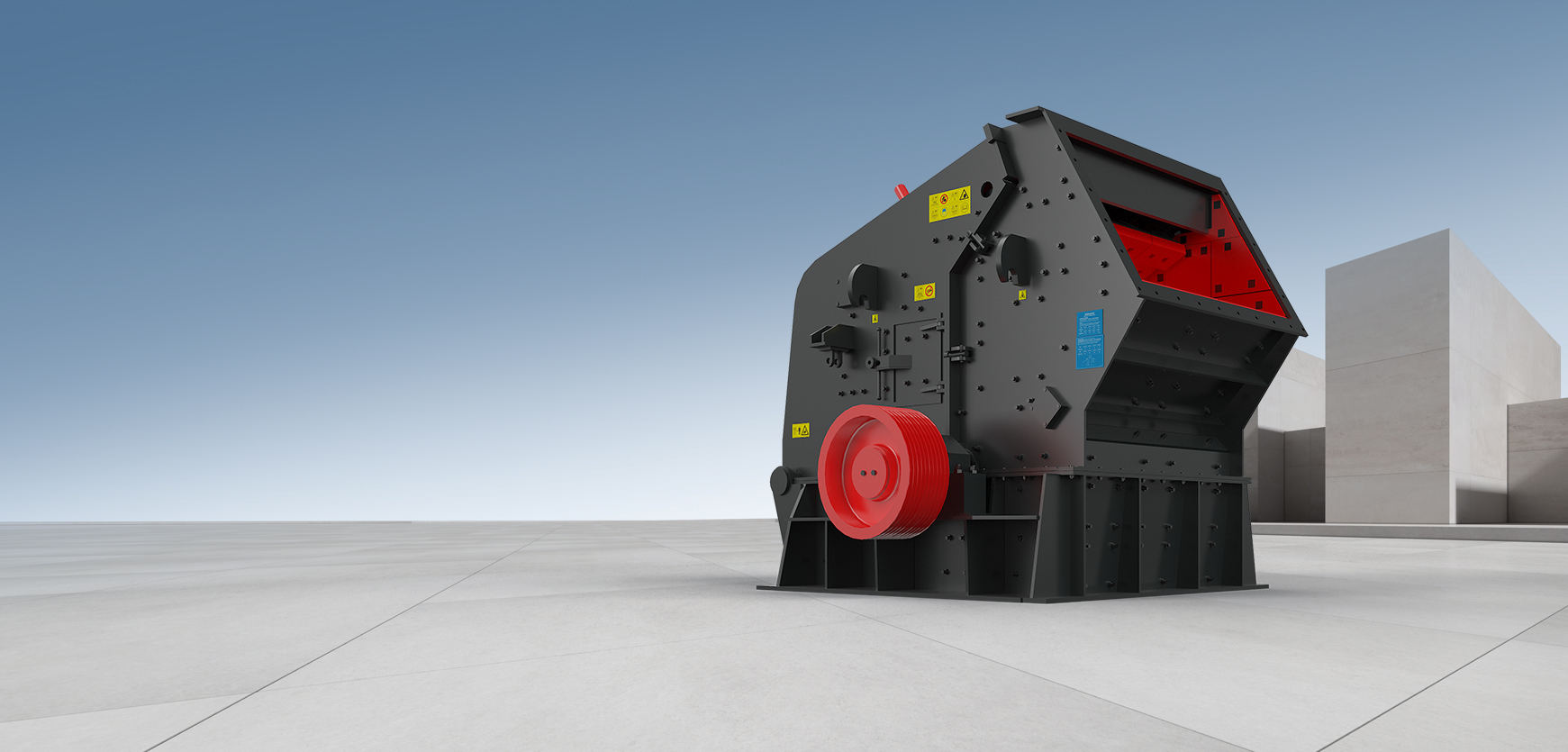

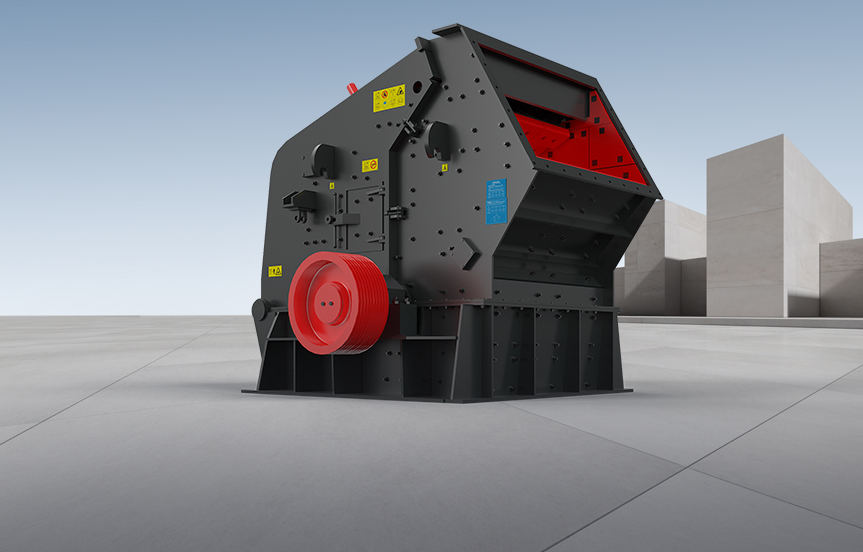

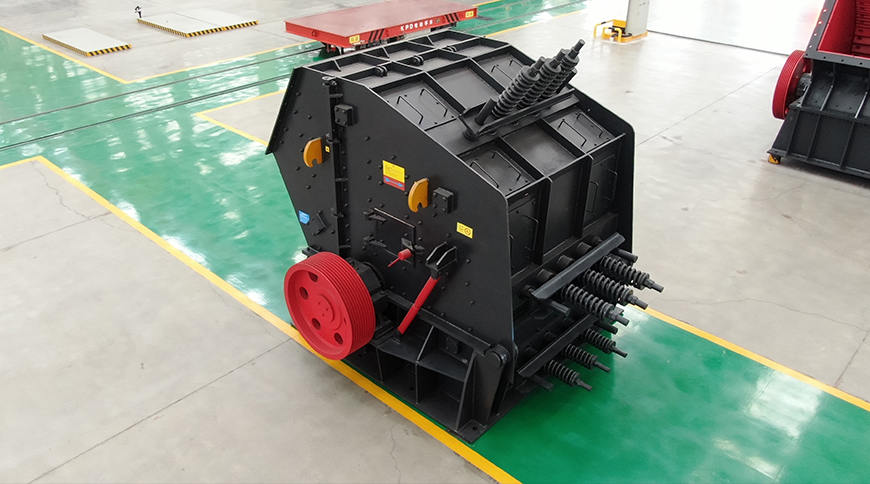

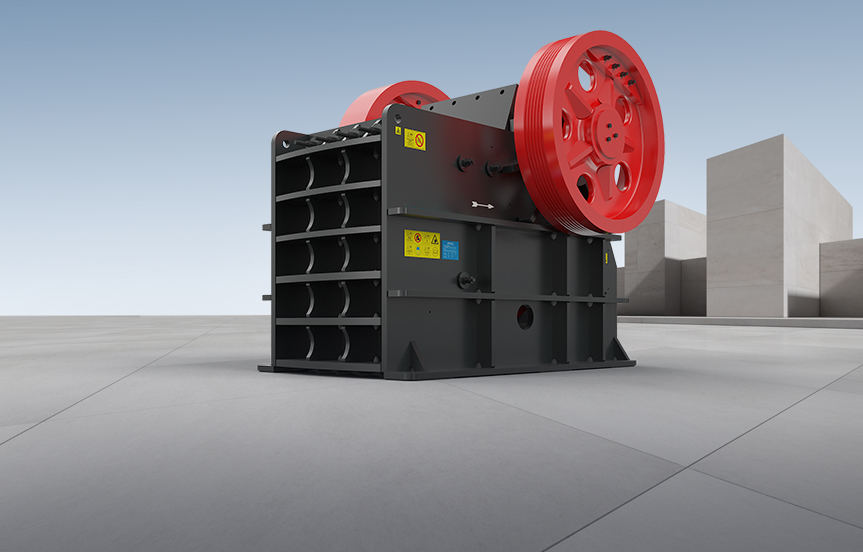

PF impact crusher is an efficient impact crusher developed by our company in absorbing advanced technologies at home and abroad and combining with the working conditions of the sand and gravel industry.

Unique structural design and advanced manufacturing technology has been adopted on this crusher design. The impact crushers are widely used in the crushing of low-abrasive materials with medium hardness and below such as railways, high-ways, energy, building materials, chemical industries and other industries.