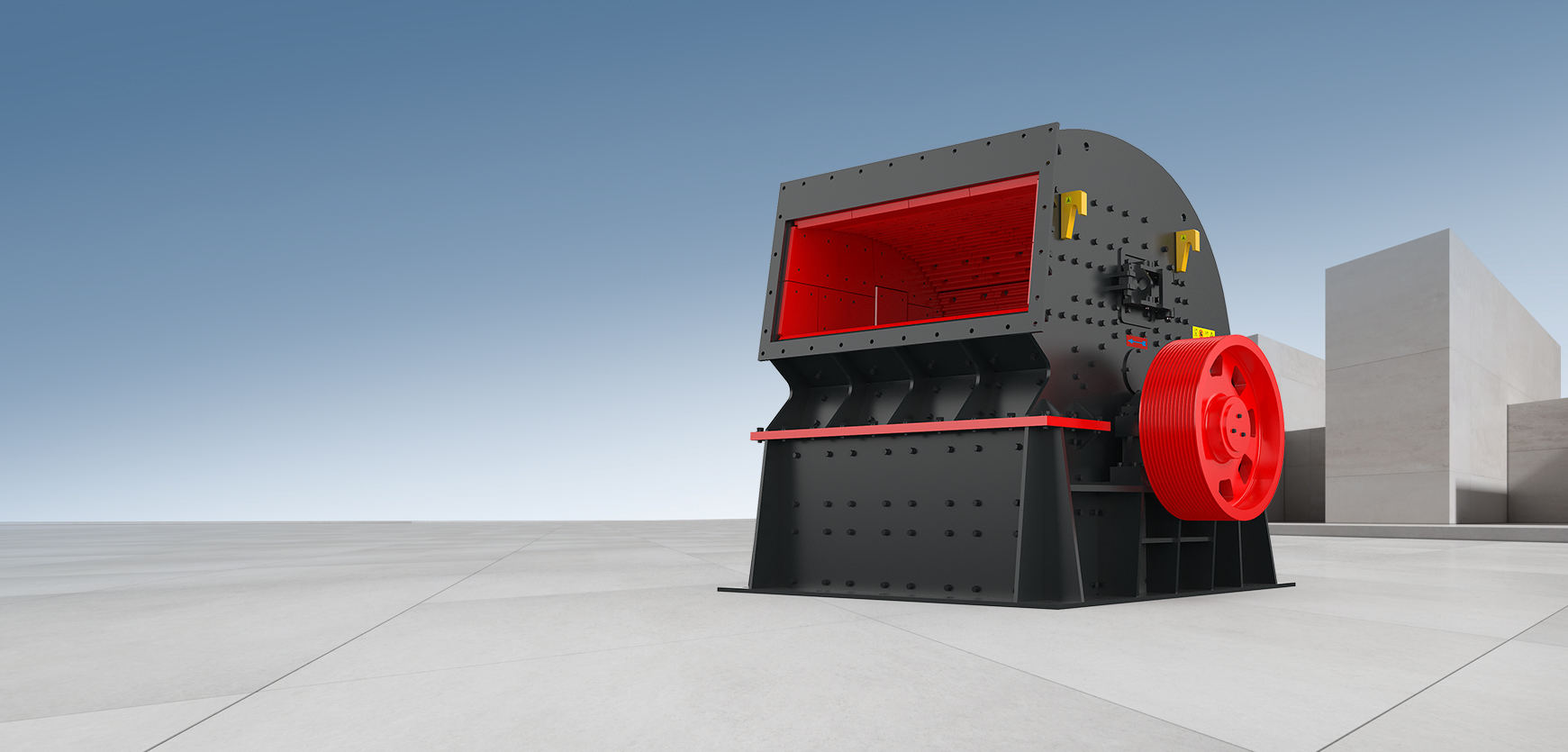

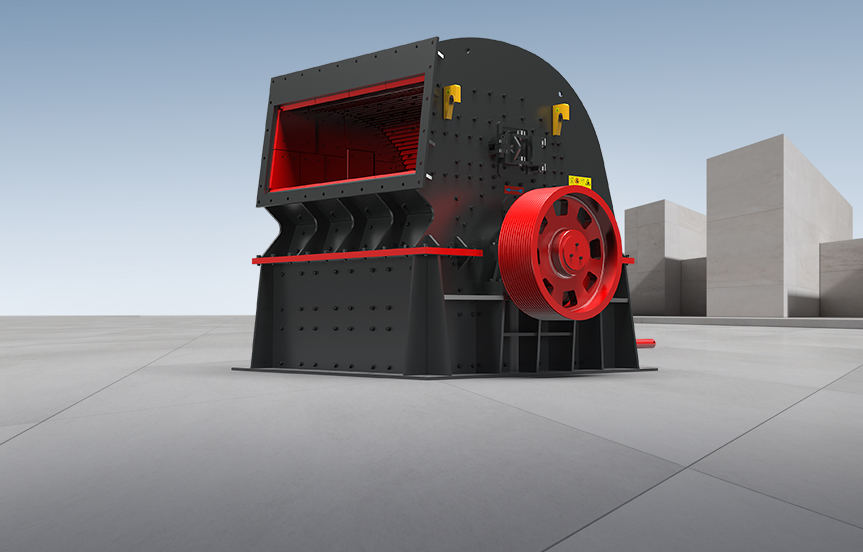

PCX type heavy hammer crusher is widely used in many industries such as mining, smelting, building materials, highway, rail-way, water conservancy and chemical industry. It is suitable for crushing various medium hardness and brittle materials with compressive strength less than 150Mpa, such as limestone, bluestone, coal gangue, etc.